This short note profiles Qnergy, the leading manufacturer of Stirling-design engines, which generate 1-10 kW of power, for remote areas, where a grid connection is not available. The units are particularly economical for mitigating methane emissions, with a potential abatement cost of $20/ton of CO2-equivalents avoided.

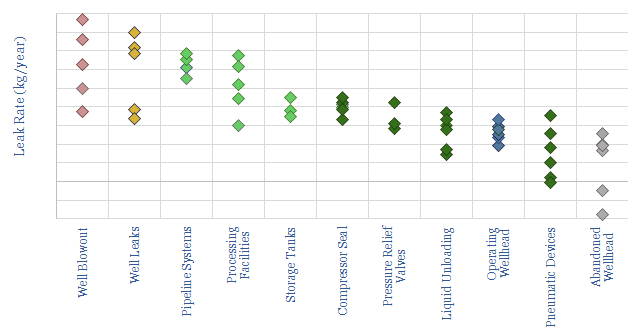

750,000 bleeding pneumatic devices around the oil and gas industry are the largest single source of methane leaks, with each medium-bleed device leaking an average of 1.5T of methane per year, comprising 35% of the oil and gas industry’s total emissions (chart below, data here).

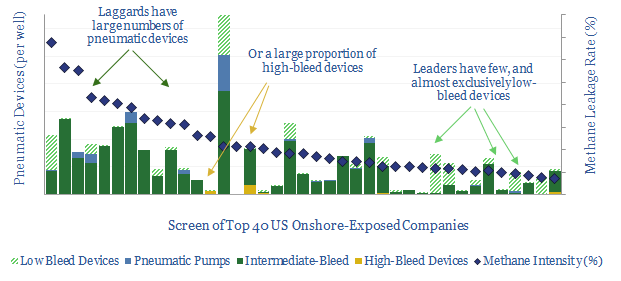

We have screened the US onshore space, operator-by-operator, acreage position by position, to see who most urgently needs to replace bleeding pneumatics (chart below, data here, note here). But how will they be replaced?

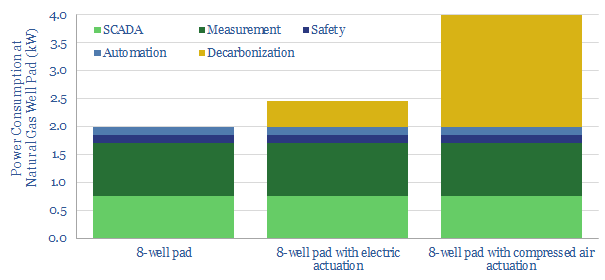

The challenge is power. An 8-well pad will typically require 2kW of electricity, which is low because the pneumatic pressure of natural gas is used in control and actuation of valves. The power demands rise to 4kW if compressed air is used in lieu of methane. Compressed air is reliable, easy to retrofit and does not cause warming when it bleeds into the atmosphere. But a compressor is needed, and the compressor needs to be powered (below).

Qnergy’s Powergen product uses a Stirling engine to generate electricity from heat. It is fuel agnostic and can run on waste heat or in-basin gas.

The PowerGen product was launched in 2017 and its adoption has been growing at a 300% CAGR. The company now also manufactures and sells compressed air pneumatic devices, which will be powered by its Stirling engines. The 5,650 series generates 5.7kW of power from 1.4mcfd of gas inputs (implying c30% thermal efficiency).

NASA has accredited the design as the most reliable ever invented for a heat engine. One of the first units has now run for 24,000 hours without requiring maintenance (equivalent to driving a car to the moon and back 2x). Design life is estimated at over 60,000 hours (7-years). The engine runs between -40C in Alaska and 60C desert installations. Each unit is also remotely monitored, with live support, for preventative maintenance and to detect issues.

Total cost of ownership for Stirling’s Powergen is cited as the lowest cost power solution to replace bleeding pneumatic devices: costing $100k for Qnergy unit, $150k for a microturbine, $320k for a combination of renewable power and fuel cells, and c$380k for a thermo-electric alternative.

Emissions reductions from each Qnergy Powergen unit saves 325T of CO2e-emissions per annum, while powering each unit will emit 25T of CO2e, for a net saving of 300T/CO2e. At a total cost of $100k, this implies a CO2 abatement cost of $20/ton over a c15-year life of a Qnergy Powergen unit.

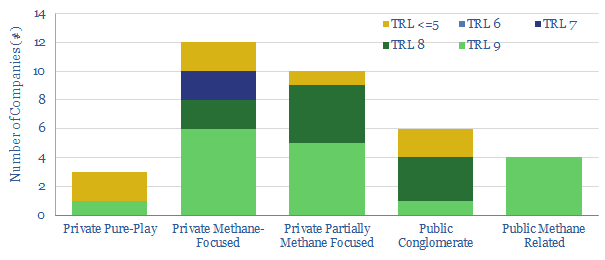

For our published screen of companies in methane mitigation, please see our data-file here.

For Qnergy’s latest presentation, see the video below, and please let us know if we can helpfully introduce you to the team at Qnergy.