Almost 1% of global CO2 comes from distillation to separate crude oil fractions at refineries. An alternative is to separate these fractions using precisely engineered polymer membranes, eliminating 50-80% of the costs and 97% of the CO2. We reviewed 1,000 patents, including a major breakthrough in 2020, which takes the technology to TRL5. Refinery membranes also comprise the bottom of the hydrogen cost curve. This 14-page note presents the opportunity and leading companies.

The CO2 intensity of refining and the need for economic decarbonization of the sector are quantified on pages 2-4. The discussion focuses upon the CO2 intensity of distillation, including the thermodynamics and costs.

The opportunity to use membranes in lieu of conventional distillation is presented on pages 5-6. We draw on economic models to present respective costs and CO2 intensities of membrane processes.

Hence we screened 1,000 patents to identify leading companies exploring refinery membranes. The findings are presented on pages 7-8. There are three key reasons why the technology has been slow to gain traction.

The most active patent filer in refinery membranes is profiled on page 9, a publicly listed conglomerate with headquarters in the US.

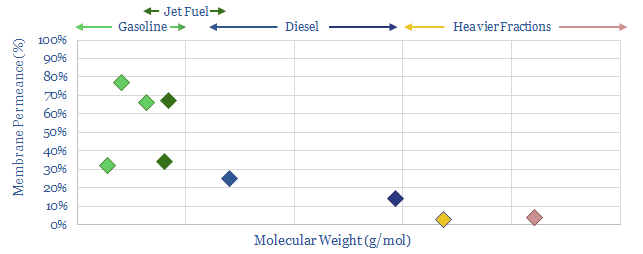

ExxonMobil has made a breakthrough in 2020, deriving permeate streams from a synthetic polymer membrane that resemble the output from a distillation column. We have reviewed the technical disclosures on pages 10-13, highlighting the commercial opportunity and remaining challenges.

Membranes can also unlock the lowest cost hydrogen in the world, recovering hydrogen that is currently wasted or purged in the effluent streams from refinery units. An industry leading example of this technology is explored on page 14.