Woody biomass can be converted into clean hydrogen via gasification. If the resultant CO2 is sequestered, each ton of hydrogen may be associated with -20 tons of CO2 disposal. The economies of hydrogen from biomass gasification require $11/kg-e revenues for a 10% IRR on capex of $3,000/Tpa of biomass, or lower, with CO2 disposal incentives.

Bright green hydrogen can be produced from woody biomass that would otherwise have decomposed, partially combusting it at 800ºC with pure oxygen, and generating hydrogen and CO2 for disposal.

Mass balances. If the partial oxidation of biomass is followed by a water-gas shift reactor, plus purification via pressure swing adsorption, then per ton of input biomass, it can yield 0.07 tons of 97-99% pure hydrogen and 21 tons of 95-99% CO2 for disposal.

In other words, biomass gasification can yield clean hydrogen as a feedstock or fuel, but it also sequesters the carbon in biomass, addressing challenges over the permanence of some nature-based CO2 removals.

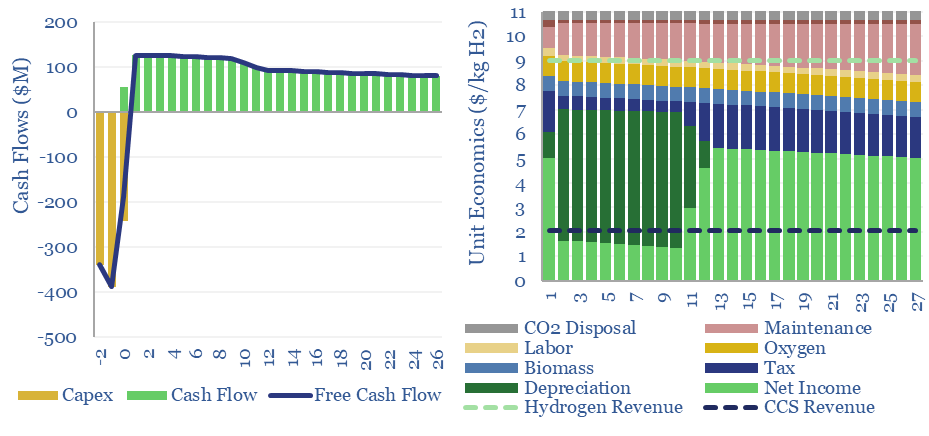

The economics of biomass gasification are modelled in this data-file, albeit screening as somewhat expensive, requiring $11/kg hydrogen-equivalent revenues to earn a 10% IRR at a gasification plant with capex of c$3,000/Tpa of biomass.

50% of the total costs are associated with covering the high capex costs, while another 5-15% ($1/kg each) can be ascribed to plant maintenance, sourcing biomass and sourcing oxygen.

$11/kg hydrogen-equivalent revenues, in turn, may be derived via any mix of hydrogen revenues and CO2 disposal revenues, such as $11/kg hydrogen and $0/ton CO2 disposal, $9/kg hydrogen and $100/ton CO2 disposal, or $1/kg hydrogen and $500/ton CO2 disposal.

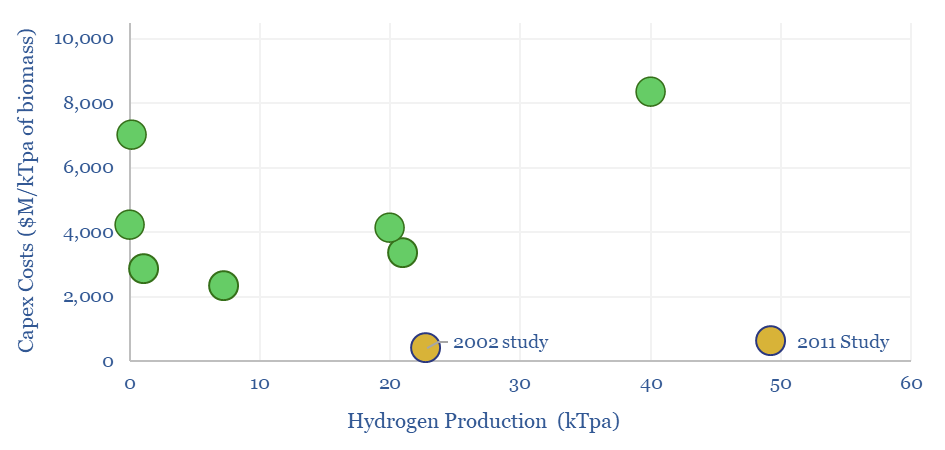

Costs of hydrogen from biomass gasification could best be reduced by reducing the capex costs of gasification facilities. Note the wide range of proposed capital investment costs in the chart below.

Energy economies are c50% energy-efficient, requiring 70 kWh of input energy per kg of hydrogen output, of which 94% is from the exothermic partial oxidation of woody biomass. Another c3% is from separating out oxygen, and another 3% is for compressing CO2.

Hence overall, gross CO2 emissions should be below 1 ton of CO2 per ton of hydrogen, while net CO2 emissions should be -20 tons of CO2 per ton of hydrogen production.

Biomass gasification adds to our list of hydrogen technologies, from black hydrogen, grey hydrogen, SMR blue hydrogen, ATR blue hydrogen, turquoise hydrogen, MIRALON process, chemical looping combustion, and green hydrogen.