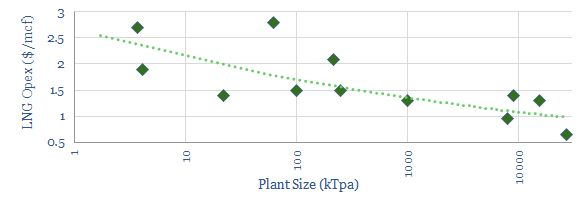

This data-file tabulates a dozen data-points on LNG plant opex, from company disclosures, the technical literature and academic papers. LNG plant opex averages $1/mcf. Opex is a function of plant size, and tends to fall by $0.3/mcf for each 10x change in plant capacity.

Liquefied natural gas (LNG) trains range from small-scale LNG at 1-100kTpa capacity through to the super-massive APX LNG trains, which are above 7MTpa each.

Or in other words, there is a 10,000x variation between the smallest and largest LNG trains installed globally. For further details, please see our overview of LNG process technologies.

A good baseline for LNG plant opex is around $1/mcf, the largest component of which is energy costs for liquefaction, and underpinning a drive for greater efficiency.

LNG opex costs are subject to economies of scale. Another good rule of thumb for LNG opex is that each 10x variation in plant capacity tends to be associated with $0.3/mcf variation in liquefaction opex.

Total delivered LNG costs, on a newbuild facility are usually in the range of $7-12/mcf, across gas production, gas processing, pipeline transportation, LNG liquefaction, LNG shipping and LNG regasification.

Another good way to understand the relative differences between the costs of LNG plants is looking in more detail into cryogenics, and the inherent benefits of larger cold boxes. A small cold box (lower volume to surface area) will leak coldness faster than a larger cold box (higher volume to surface area). Our best discussion on this topic is here.

This simple data-file aims to provide an array of data-points for how LNG plant opex varies with plant size, based on disclosures we have seen in the academic and technical literature.

Please see our LNG category page for all of our key conclusions into LNG in the energy transition.