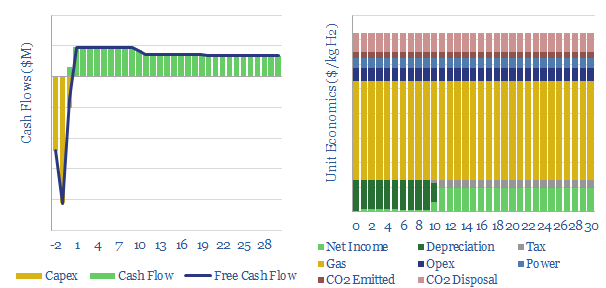

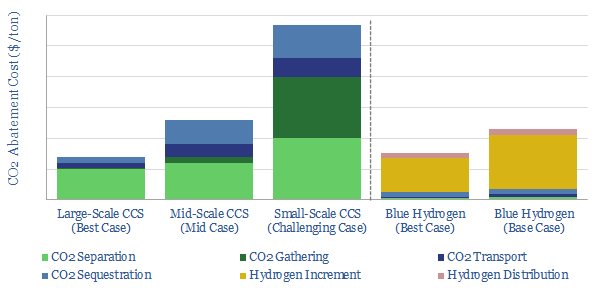

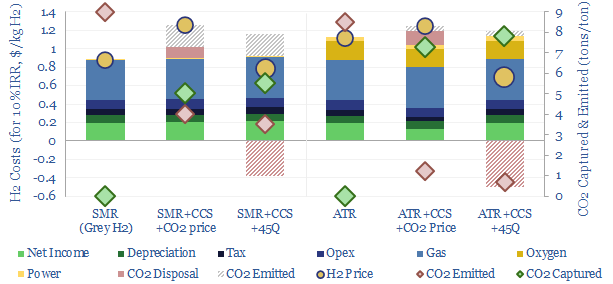

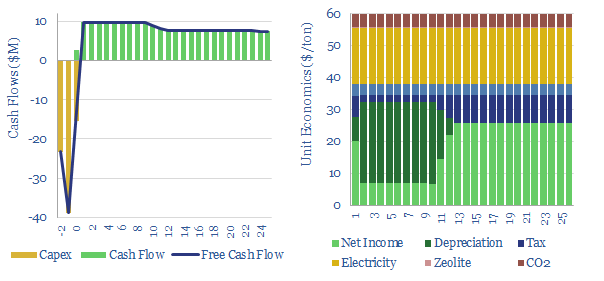

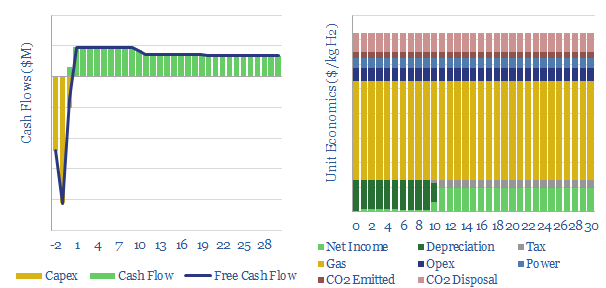

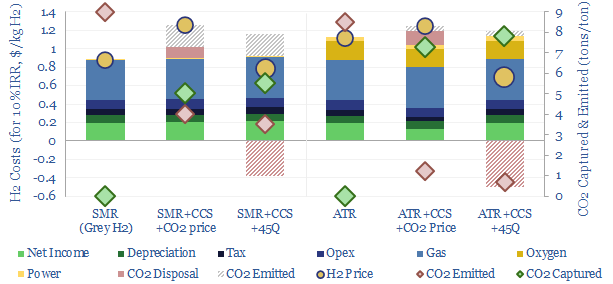

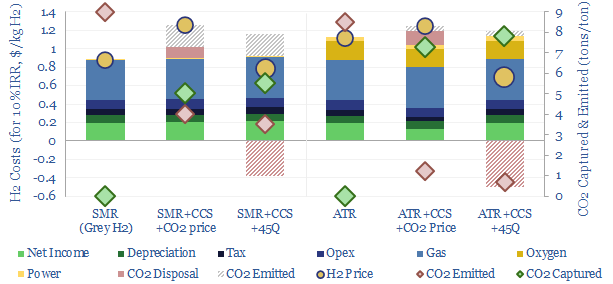

This data-file captures the costs of hydrogen production via reforming natural gas, either via steam-methane reforming (SMR) or autothermal reforming (ATR). Our base case costs of grey hydrogen are $0.6-0.9/kg,…

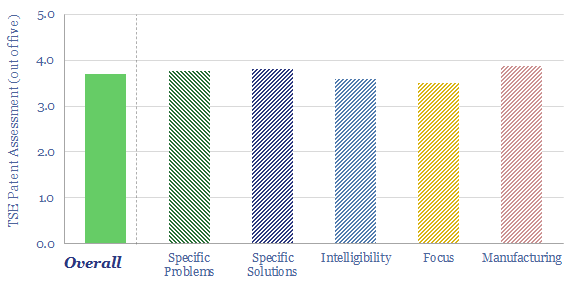

Topsoe autothermal reforming technology aims to maximize the uptime and reliability of blue hydrogen production, despite ultra-high combustion temperatures from the partial oxidation reaction, while achieving high energy efficiency, 90-97%…

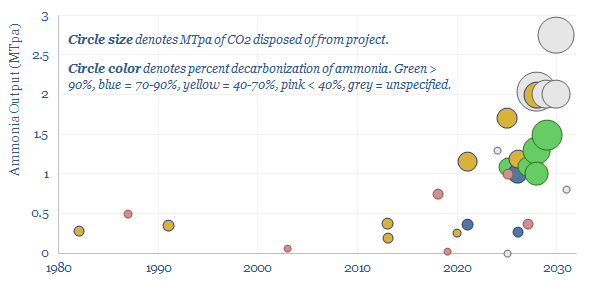

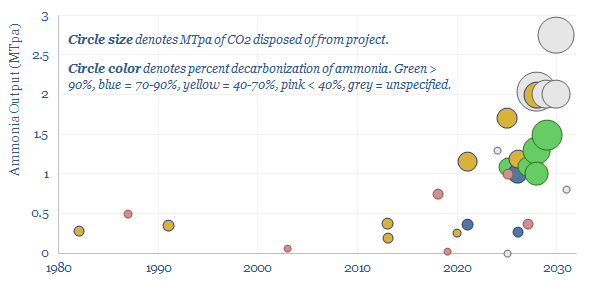

…gas reforming. One limitation has been the use of SMRs for gas reforming, whereas ATRs should allow higher rates of CO2 capture in the future (note here). A growing interest…

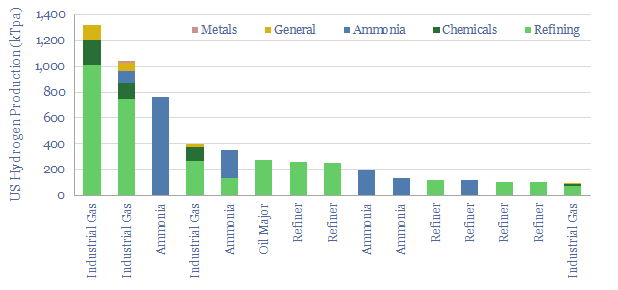

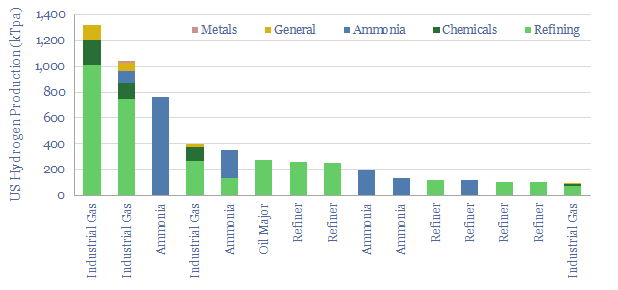

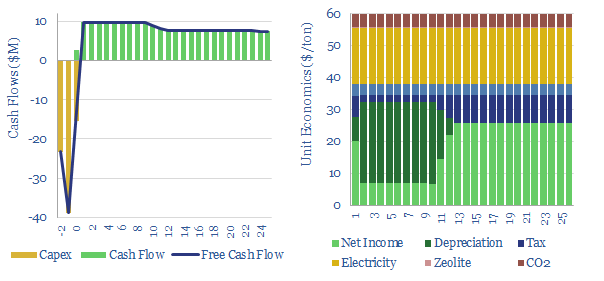

…in chemicals/methanol. This datafile breaks down US hydrogen production by facility. Owners of existing steam methane reforming units may readily be able to capture CO2 and benefit from CO2 disposal…

…12. Different blue hydrogen reactor designs are discussed, and their economics are modelled on pages 13-15. Autothermal reforming should take precedence over steam methane reforming as part of the energy…

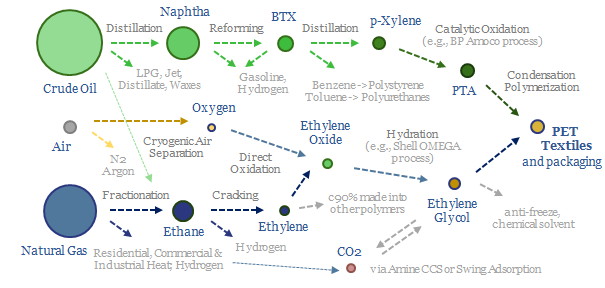

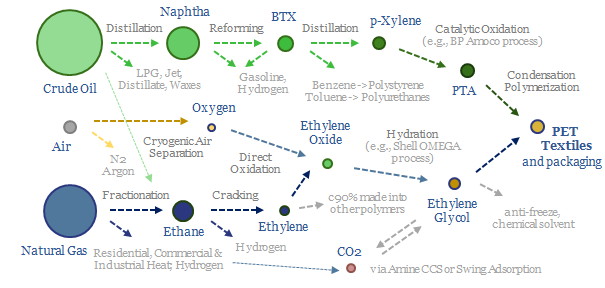

…that span naphtha-reforming, BTX separation into paraxylene, oxidation to PTA, plus ethane cracking, ethylene oxide and ethylene glycol. This data file covers the polyester production process, step by step, including…

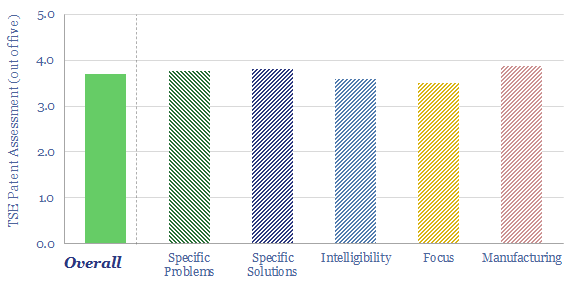

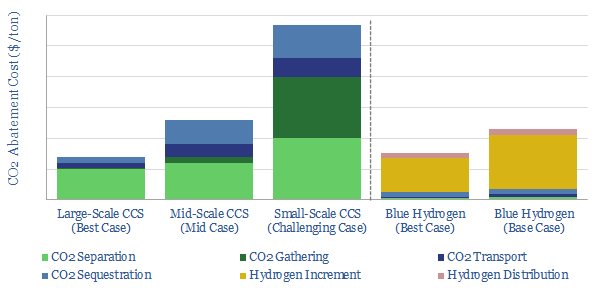

Blue hydrogen value chains are gaining momentum. Especially in the US. So this 16-page note contrasts steam-methane reforming (SMR) versus autothermal reforming (ATR). Each of these different hydrogen reformers has…

Blue hydrogen value chains are gaining momentum. Especially in the US. So this 16-page note contrasts steam-methane reforming (SMR) versus autothermal reforming (ATR). Each has merits and challenges. ATR looks…

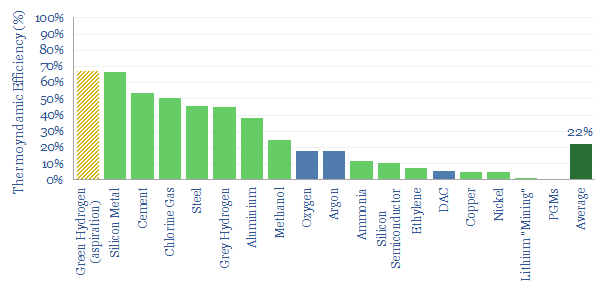

…its constituent elements, i.e., gaseous hydrogen and gaseous nitrogen. Pure hydrogen does not occur naturally, but itself needs to be produced, most likely by steam methane reforming. And pure nitrogen…

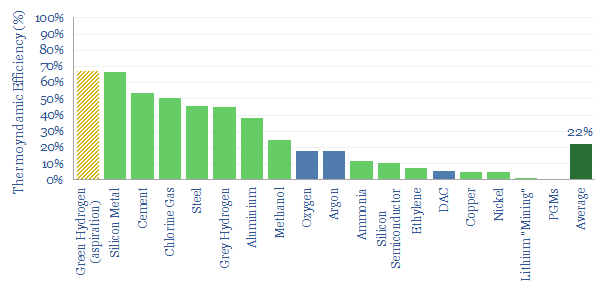

Pressure swing adsorption purifies gases according to their differing tendencies to adsorb onto adsorbents under pressure. Pressure swing adsorption costs <$0.1/kg when separating pure hydrogen from the output of reforming…