Topsoe autothermal reforming technology aims to maximize the uptime and reliability of blue hydrogen production, despite ultra-high combustion temperatures from the partial oxidation reaction, while achieving high energy efficiency, 90-97% CO2 capture and <1 kg/kg CO2 intensity. This is achieved via twelve technology innovations.

Topsøe is a chemicals technology company, privately owned, headquartered in Denmark, founded in 1940, with 2,400 employees, $1bn of revenues in 2022 and 10% EBIT margin.

Topsoe’s technology focuses include gas reforming into syngas, comprising hydrogen and carbon monoxide; downstream value chains that use the components such as refinery processes, renewable fuels, low-carbon hydrogen, ammonia, dimethyl ether, methanol, synthetic natural gas and sulfuric acid.

This data-file is focused on Topsoe’s autothermal reforming technology, for the production of blue hydrogen, which matters increasingly as blue ammonia and blue steel value chains start booming in the US.

Topsoe’s ATR design, called SynCor, has been deployed commercially since 2002, and may be the leading ATR technology in the marketplace in the early-2020s. Some examples of commercial deployments are noted in the data-file.

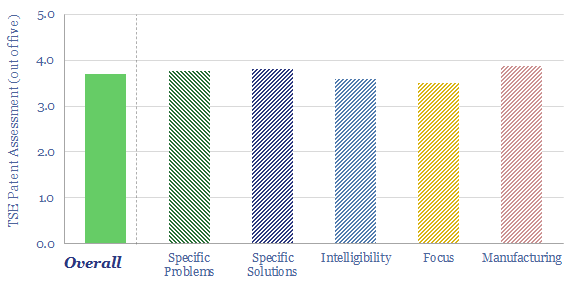

Advantages of Topsoe’s ATR technology are said to include high uptime, “best in class” energy intensity, 90-97% CO2 capture, <1 kg CO2/kg H2. But how is this being achieved, and how much of it is patent protected?

The first step of blue hydrogen reforming is a partial oxidation reaction, combusting methane with pure oxygen from an air separator, to produce CO and H2. This burner runs extremely hot. Flame temperatures reach 2,500-3,000ºC, and even by the upper portions of the catalyst bed, temperatures are still 850-1,100ºC.

High temperatures in context? You can compare this with the heating-melting temperatures of materials, maximum temperatures of structural materials, typical combustion temperatures, typical refinery processes and the hottest gas turbines.

These high temperatures cause unavoidable volatilization of materials, even refractory lining materials. Volatilized materials are later prone to being deposited on the catalyst beds. Or catalysts may be directly deactivated by exposure to excessively hot temperatures. Conversely, protecting the catalysts from very high temperatures causes pressure drops and energy penalties.

Overall, this means that key challenges for blue hydrogen reactors include reliability, uptime and maximizing energy efficiency.

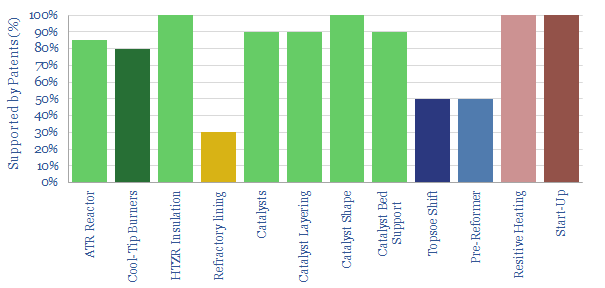

Twelve innovations from Topsoe are discussed in the data-file, to address these challenges. In each case, we have aimed to explain what the innovation is, why it matters, and whether we can find support for the innovation via Topsoe’s patents.

There are alternative designs for blue hydrogen production, however our patent review leads us to wonder whether they will have lower rates of CO2 capture (e.g., KBR technology) or lower uptime and resiliency.

Our updated model of blue hydrogen costs integrates some of the considerations from this data-file and blue hydrogen technology review.