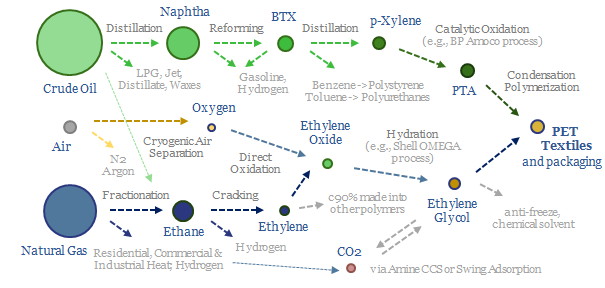

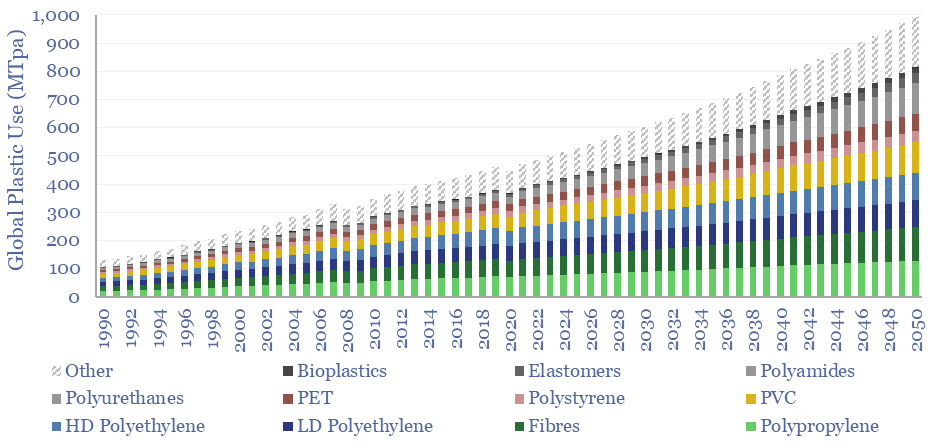

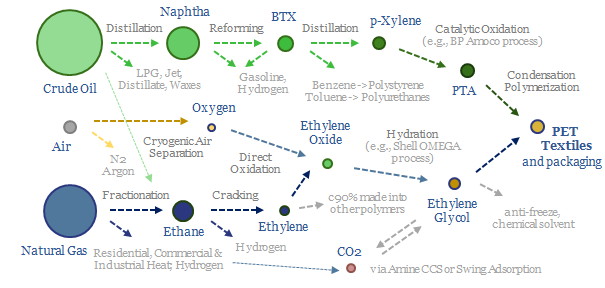

…that span naphtha-reforming, BTX separation into paraxylene, oxidation to PTA, plus ethane cracking, ethylene oxide and ethylene glycol. This data file covers the polyester production process, step by step, including…

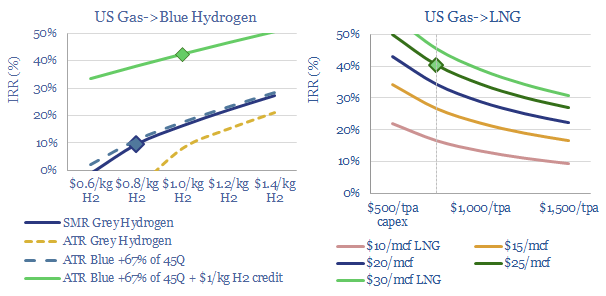

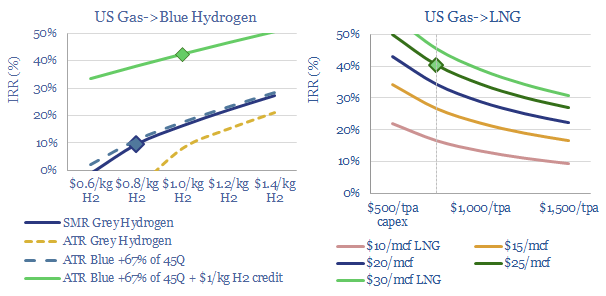

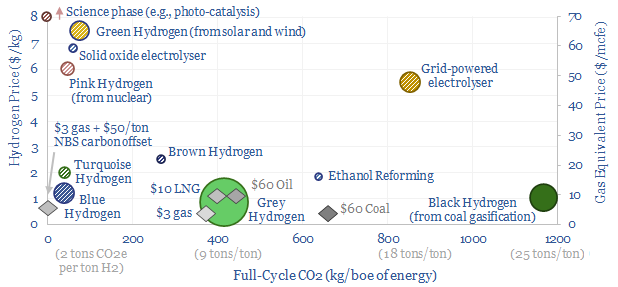

…0.5-1.5 kg/kg CO2 intensity), this will uplift ATR IRRs above 40% (chart below). https://thundersaidenergy.com/downloads/blue-hydrogen-from-methane-reforming-the-economics/ How will the blue hydrogen boom impact US gas demand? This is hard to quantify, because…

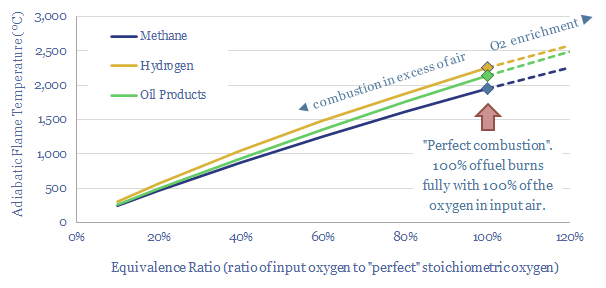

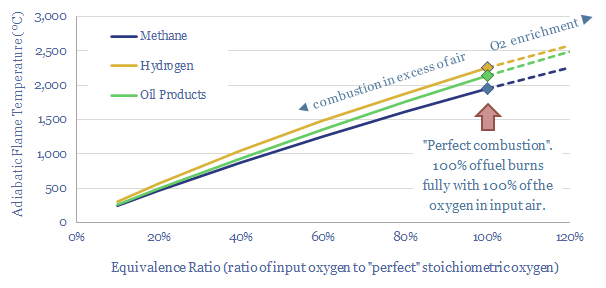

…in online resources such as Wikipedia. Why does adiabatic flame temperature matter in industry? Very hot process temperatures are needed for producing many metals, materials and in some hydrogen reforming…

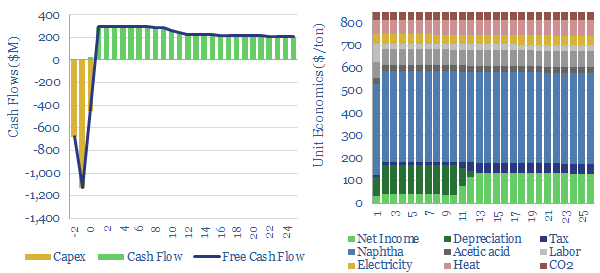

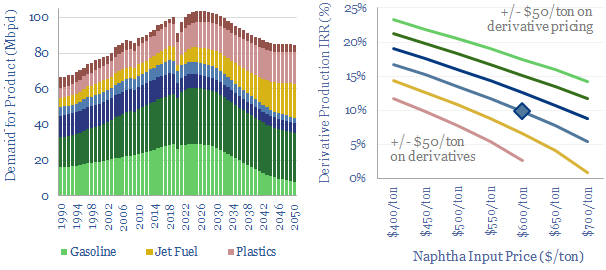

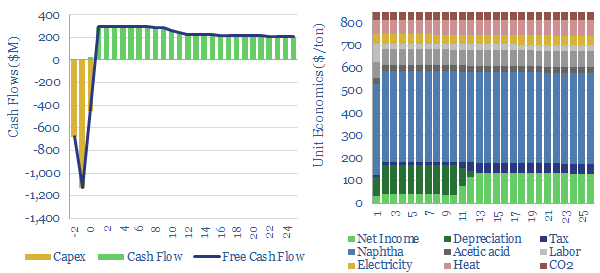

…process heat for the cracking/reforming of naphtha. Energy costs are a major contributor to PX production costs, but less significant for oxidizing PX into PTA. How does the cost of…

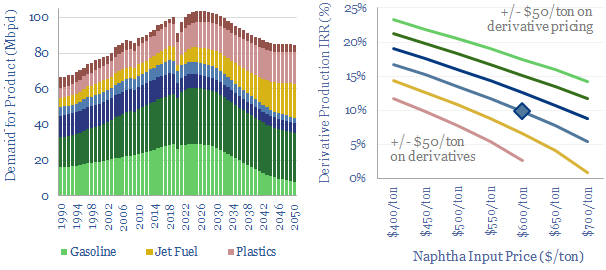

…usable in the plastics industry. They are BTXs, i.e., benzene, toluene and xylenes, produced by reforming of naphtha, and mostly flowed into the gasoline pool today, due to their excellent…

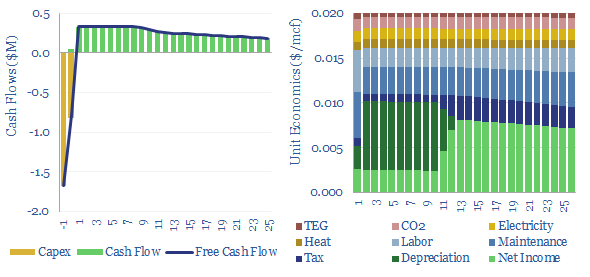

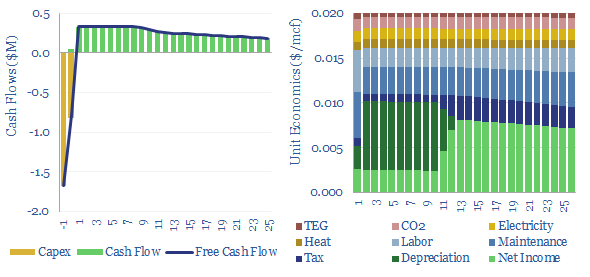

…reforming unit or some electrolysis plants. Gas dehydration most commonly takes place by absorbing the water in tri-ethylene glycol (TEG). TEG acts as a solvent for water at ambient temperatures…

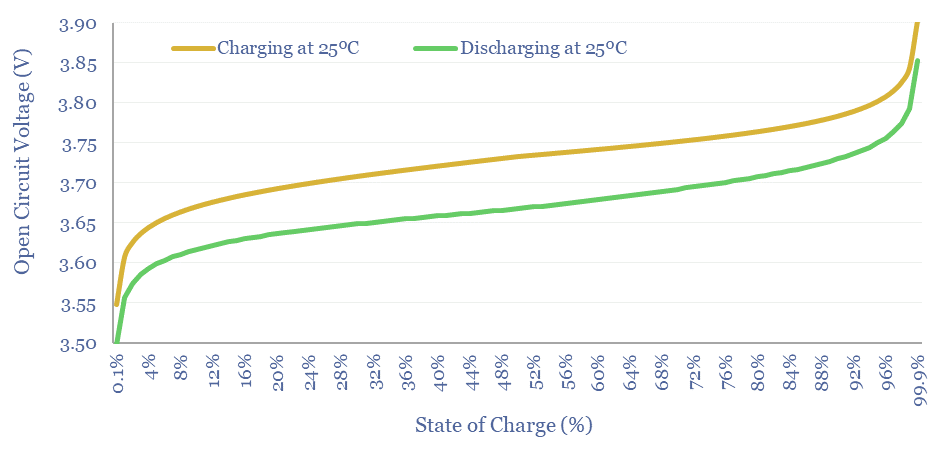

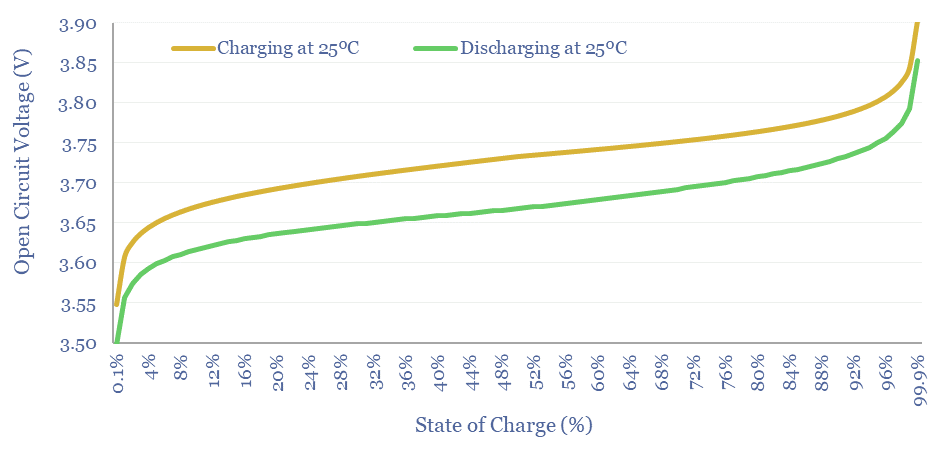

…reduce, accepting an electron from a second electrode, and re-forming H2 gas. The chemical reaction is Li + H+ -> Li+ 0.5 H2. The thermodynamic result is that energy has…

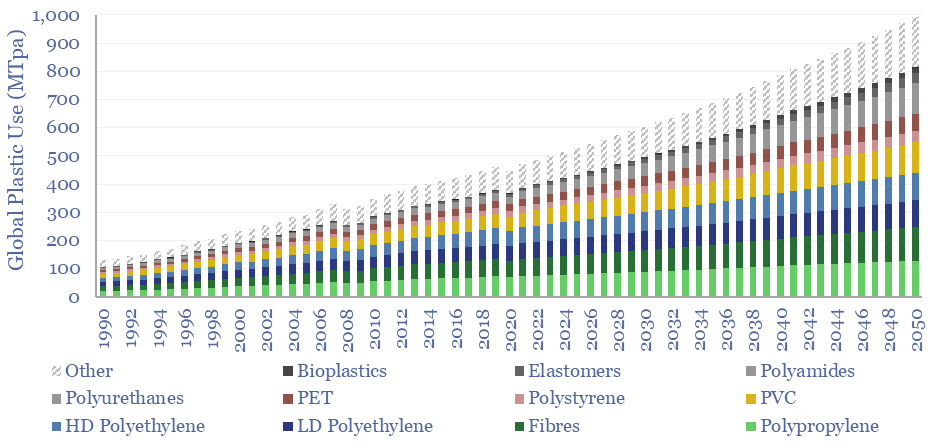

…a defining theme in the energy transition, as many polymers draw inputs from the catalytic reforming of naphtha. Today, 70% of BTX reformate is blended into gasoline, but we see…

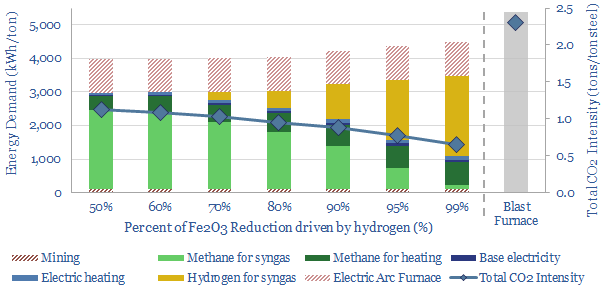

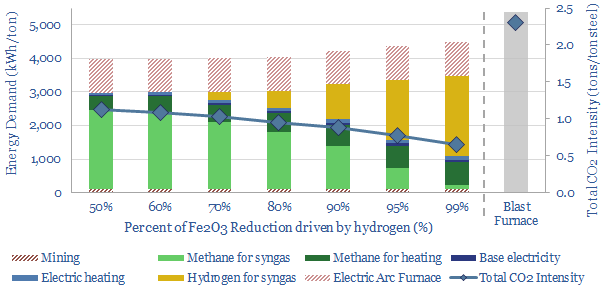

…and CO, formed by reforming natural gas. But the higher the share of hydrogen, the lower the CO2, and thus there is opportunity to add merchant hydrogen to DRIs. Existing…

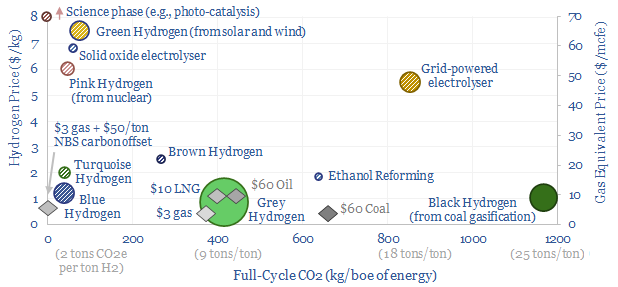

…decarbonizing natural gas at source, by reforming the methane molecule into H2 and CO2, the latter of which is sent directly for CCS. Our best overview of the topic is…