Search results for: “fertilizer ammonia”

-

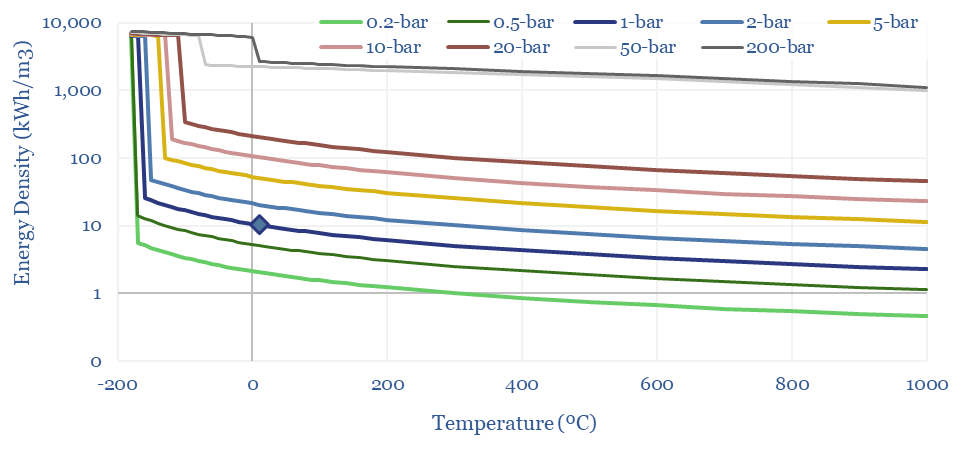

Density of gases: by pressure and temperature?

The density of gases matters in turbines, compressors, for energy transport and energy storage. Hence this data-file models the density of gases from first principles, using the Ideal Gas Equations and the Clausius-Clapeyron Equation. High energy density is shown for methane, less so for hydrogen and ammonia. CO2, nitrogen, argon and water are also captured.

-

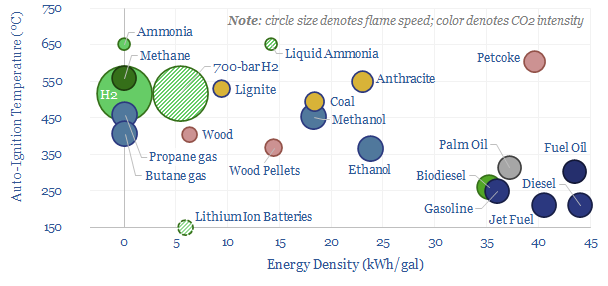

Combustion fuels: density, ignition temperature and flame speed?

The quality of a combustion fuel comes down to its physical and chemical properties. Hence the purpose of this data-file is to aggregate data into different fuels’ energy content (kg/m3), energy density (kWh/kg, kWh/gal), flash point (ºC), auto-ignition point (ºC) and flame speed (m/s, cm/s). Conclusions about high quality fuels follow.

-

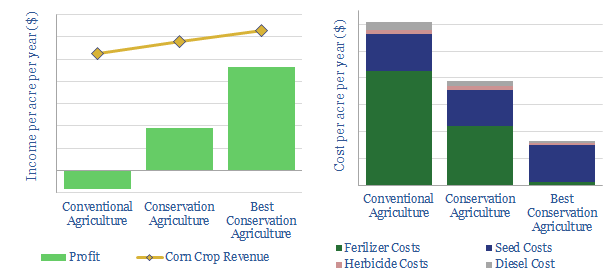

Restoring soil carbon: the economics?

We model the economics for conservation agriculture to restore soil carbon. 5-30T of CO2 can be sequestered per acre per year, while deflating farm costs by 36-73% and raising yields 10-20%. This would transform crop-growing economics from marginal to material.

-

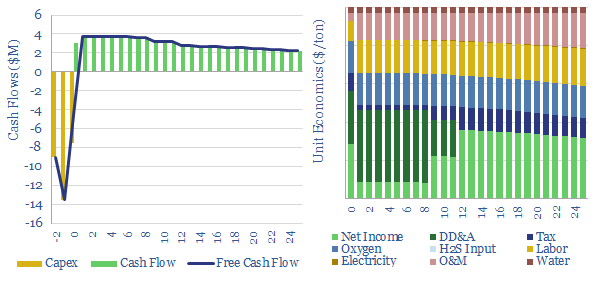

Sulphur recovery units: Claus process economics?

This data-file captures the economics of producing sulphur from H2S via the Claus process, yielding an important input for phosphate fertilizers and metals. Cash costs are $40-60/ton and marginal costs are $100/ton. CO2 intensity is low at 0.1 tons/ton. Data-file explores shortages in energy transition?

-

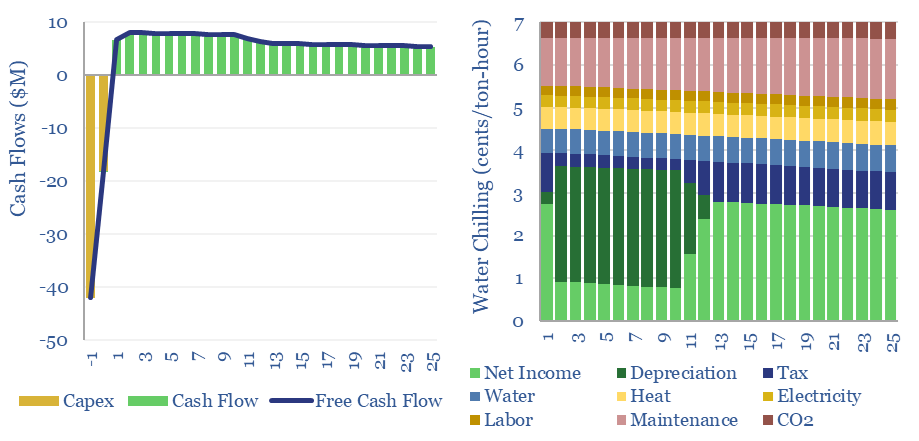

Absorption chillers: the economics?

Absorption chillers perform the thermodynamic alchemy of converting waste heat into coolness. Capex costs of absorption chillers average $600/kW-th and all-in absorption chiller costs run to 6-7 cents/ton-hour, depending on the price of incoming waste heat. This data-file captures the economics of absorption chillers from first principles.

-

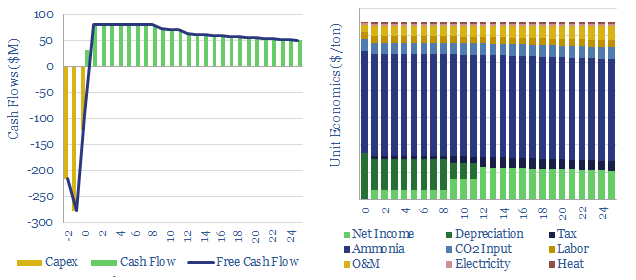

Urea production: the economics

This data-file captures the economics of producing urea, an important fertilizer and intermediate material. We estimate a marginal cost of $325/ton, based on $2/mcf-e energy inputs. CO2 intensity is 1.5 tons/ton. But costs will increase well above $800/ton during times of energy shortages.

-

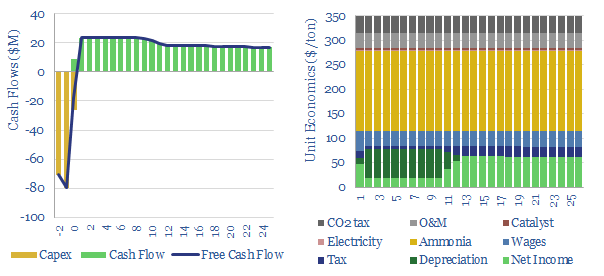

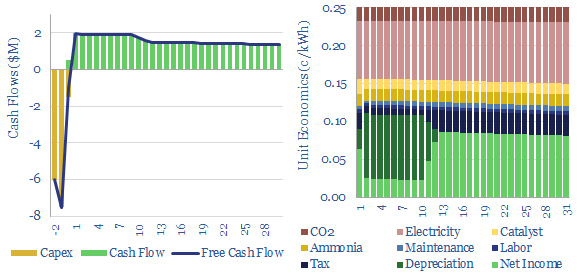

Nitric acid: production costs?

Global production of nitric acid is 60MTpa, in a $25bn pa market, spanning c500 production facilities. This data-file estimates a marginal cost of $350/ton HNO3 and a CO2 intensity averaging 1.8 tons/ton. There are feedback loops where gas shortages could result in fertilizer and metal shortages.

-

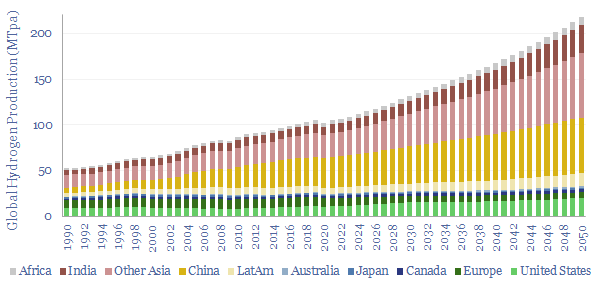

Global hydrogen supply-demand: by region, by use & over time?

Global production of hydrogen is around 110MTpa in 2023, of which c30% is for ammonia, 25% is for refining, c20% for methanol and c25% for other metals and materials. This data-file estimates global hydrogen supply and demand, by use, by region, and over time, with projections through 2050.

-

Topsoe: autothermal reforming technology?

Topsoe autothermal reforming technology aims to maximize the uptime and reliability of blue hydrogen production, despite ultra-high combustion temperatures from the partial oxidation reaction, while achieving high energy efficiency, 90-97% CO2 capture and

-

Selective catalytic reduction: costs of NOx removal?

This data-file captures selective catalytic reduction costs to remove NOx from the exhaust gas of combustion boilers and burners. Our base case estimate is 0.25 c/kWh at a combined cycle gas plant, which equates to $4,000/ton of NOx removed. Capex costs, operating costs, coal plants and marine fuels can be stress-tested in the model.

Content by Category

- Batteries (89)

- Biofuels (44)

- Carbon Intensity (49)

- CCS (63)

- CO2 Removals (9)

- Coal (38)

- Company Diligence (95)

- Data Models (840)

- Decarbonization (160)

- Demand (110)

- Digital (60)

- Downstream (44)

- Economic Model (205)

- Energy Efficiency (75)

- Hydrogen (63)

- Industry Data (279)

- LNG (48)

- Materials (82)

- Metals (80)

- Midstream (43)

- Natural Gas (149)

- Nature (76)

- Nuclear (23)

- Oil (164)

- Patents (38)

- Plastics (44)

- Power Grids (130)

- Renewables (149)

- Screen (117)

- Semiconductors (32)

- Shale (51)

- Solar (68)

- Supply-Demand (45)

- Vehicles (90)

- Wind (44)

- Written Research (354)