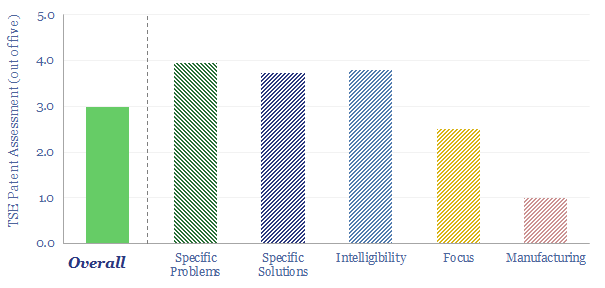

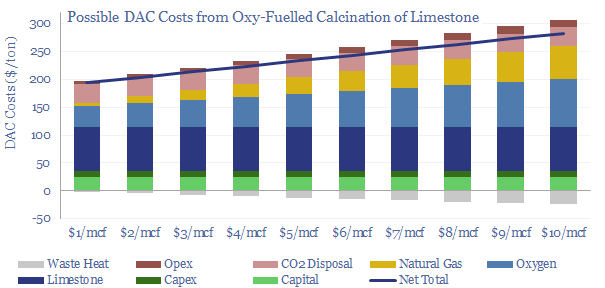

Origen Carbon Solutions is developing a novel DAC technology, producing CaO sorbent via the oxy-fuelled calcining of limestone with no net CO2 emissions. It is similar to the NET Power cycle, but adapted for a limestone kiln. The concept is very interesting. Our base case costs are $200-300/ton of CO2. This data-file contains our Origen DAC technology review.

Origen Carbon Solutions was spun-out from the University of Oxford in 2013, now has around c50 employees and is privately owned, with recent capital from HBM Holdings, Elemental Exelerator and Frontier (i.e., Stripe, Google, Meta).

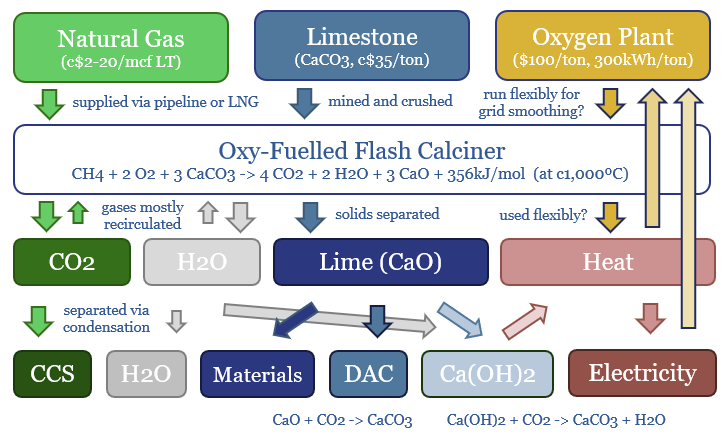

The ZerCal process, being piloted by Origen in 2023, aims to decompose limestone (CaCO3) using an oxy-fired flash calcining process which emits no net CO2. The CaO can then be used as a DAC sorbent, reacting with atmospheric CO2 to form CaCO3 solids.

A key challenge in post-combustion CCS is the need to separate CO2 (4-40% concentration) from air (mostly nitrogen). Amines can do this, but the process is costly, energy intensive and amines can be degraded by contaminants.

Oxy-combustion is an alternative approach that avoids introducing air/nitrogen into the combustion process, instead re-circulating exhaust gases, and then adding pure oxygen from an air separation unit or swing adsorption plant.

Hence the post-combustion reaction products are limited to CO2 and water (i.e., there is no nitrogen). CO2 and H2O can easily be separated. In the power sector, a similar approach is famously being taken by NET Power to produce very low-carbon gas power.

Oxy-combustion in limestone kilns is covered in Origen’s patents (schematic below). Note that this is different from other DAC designs. It is not an L-DAC design, nor an S-DAC design, nor an E-DAC design, but an oxy-fired combustion design.

DAC costs of $200-300/ton may be achievable based on simple, back-of-the-envelope calculations, using Origen’s patent disclosures. Please download the data-file to stress-test capex costs, gas prices, oxygen costs, limestone costs, and other opex.

CaO is an interesting DAC sorbent because it will slowly react with ambient CO2 without having to incur the high energy costs of fans and blowers. It could work well in petroleum basins with stranded gas that might otherwise be flared.

Another advantage that is cited in the patents is that the oxygen plant and excess heat from the oxy-fuelled calcining reaction can demand shift to help backstop (increasingly volatile) power grids (i.e., a ‘smooth operator‘), including amidst the build out of renewables.

Another particularly interesting patent adapts the process to oil shale that contains over c20% organic material and over c30% carbonate. It is noted that oxy-fired combustion of this low-grade resource could generate heat and electricity, its own CO2 could be captured directly from the plant, while the ‘waste product’ of CaO could be used as a DAC sorbent (see row 8 of the Patents tab for some mind-blowing numbers!).

Our Origen DAC technology review draws out details from these disclosures, excitement over the concept, and key question marks that remain for de-risking commercialization.