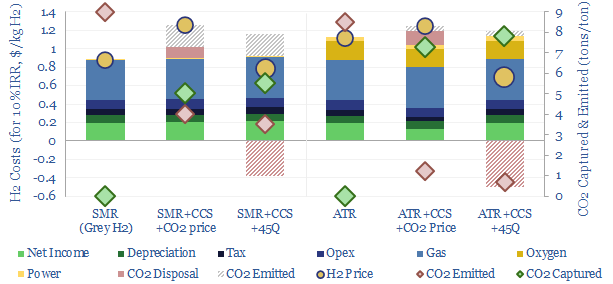

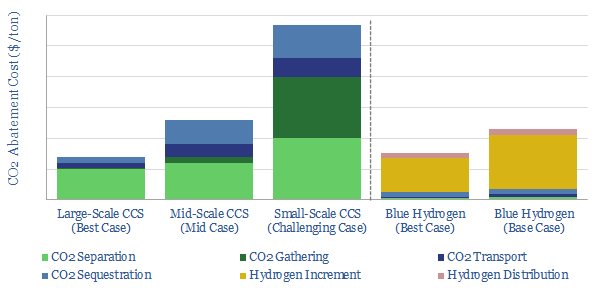

Blue hydrogen value chains are gaining momentum. Especially in the US. So this 16-page note contrasts steam-methane reforming (SMR) versus autothermal reforming (ATR). Each of these different hydrogen reformers has…

…from steam methane reforming of natural gas (grey hydrogen). Please see our overview of hydrogen technologies. As part of the energy transition, preserving a future for clean coal, it is…

…its constituent elements, i.e., gaseous hydrogen and gaseous nitrogen. Pure hydrogen does not occur naturally, but itself needs to be produced, most likely by steam methane reforming. And pure nitrogen…

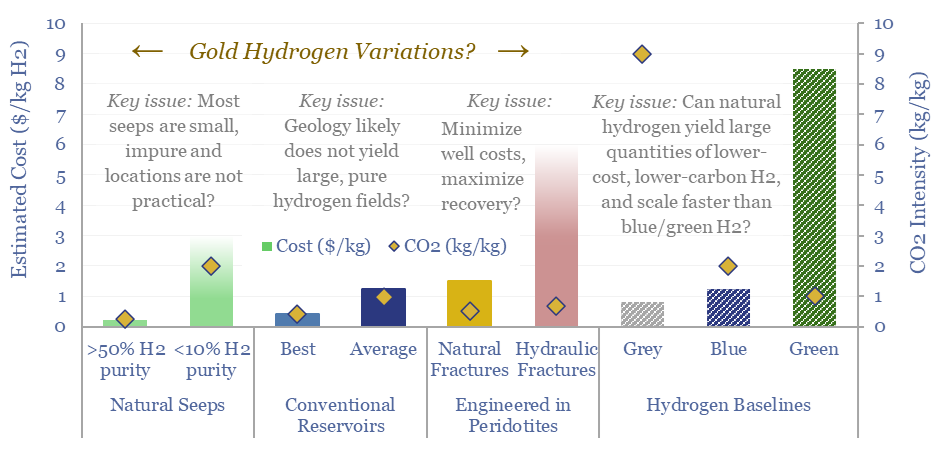

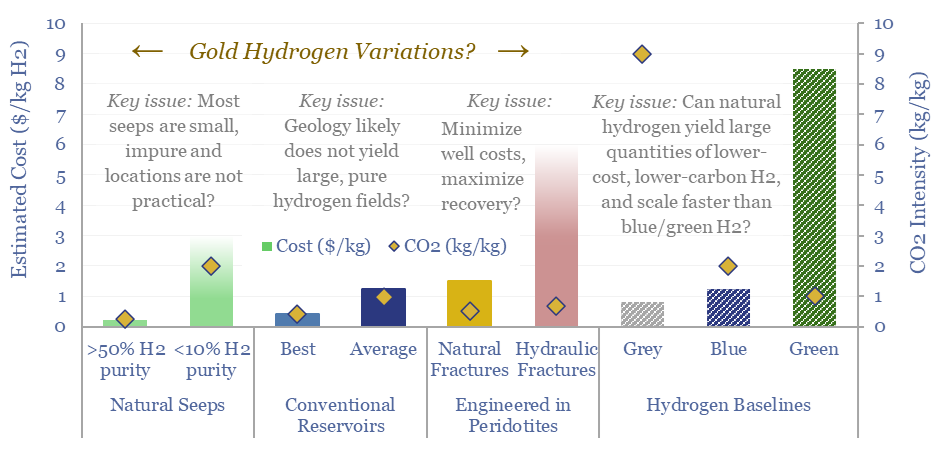

Vast quantities of gold hydrogen are produced in the Earth’s subsurface, via the serpentinization of iron-containing Peridotite rocks. Gold, white and orange hydrogen variations aim to harness this hydrogen. This…

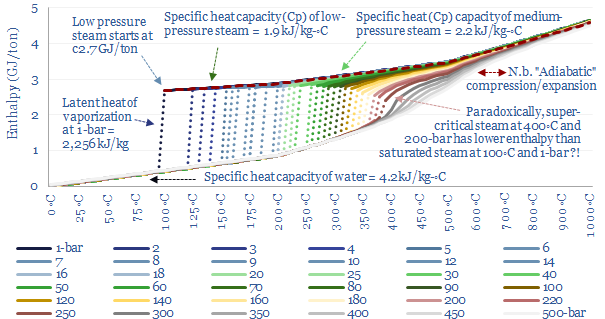

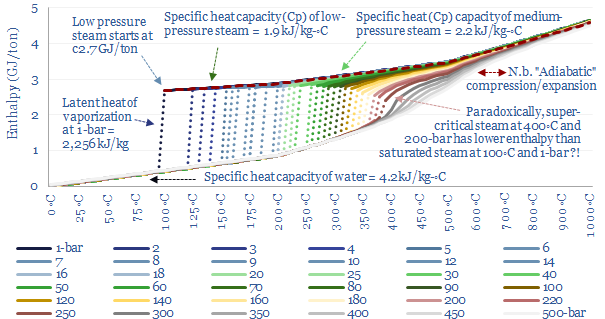

This data-file quantifies the energy needed to produce steam, for industrial heat, power, chemicals, CCS plants and hydrogen reforming. As rules of thumb, low pressure saturated steam at 100◦C requires…

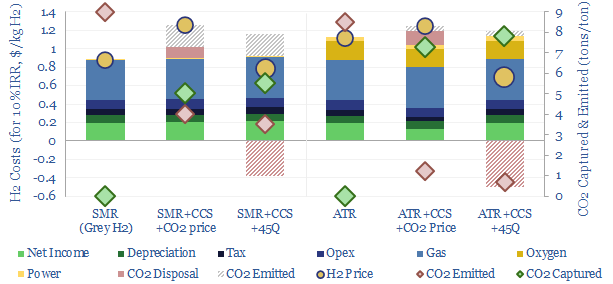

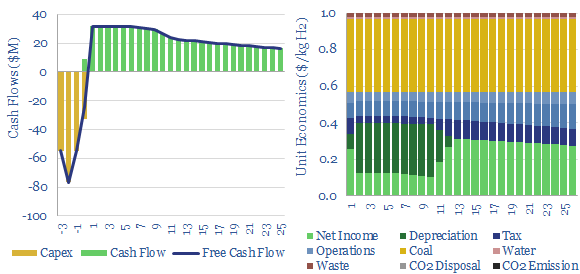

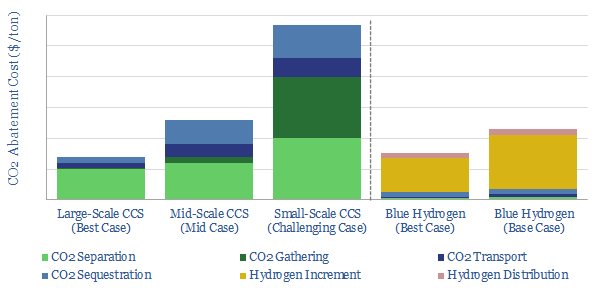

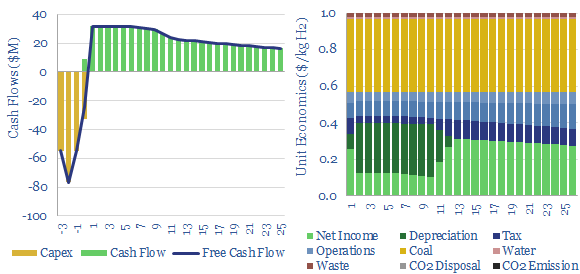

…12. Different blue hydrogen reactor designs are discussed, and their economics are modelled on pages 13-15. Autothermal reforming should take precedence over steam methane reforming as part of the energy…

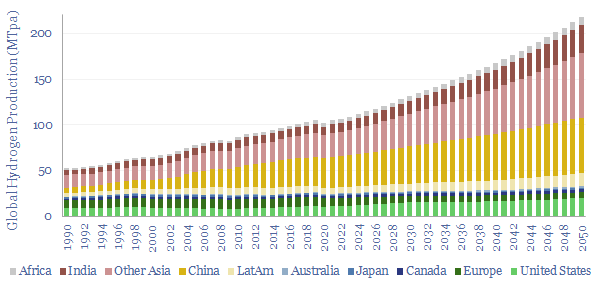

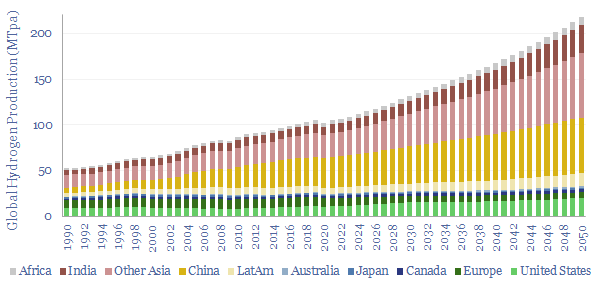

…comprising 85MTpa of grey hydrogen emitting 9 tons/ton of CO2 and 25MTpa of black hydrogen emitting 25 tons/ton of CO2. The purpose of this global hydrogen supply model is to…

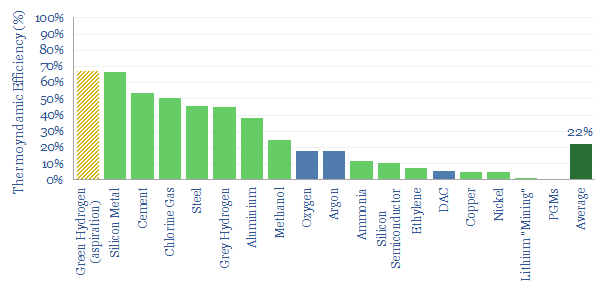

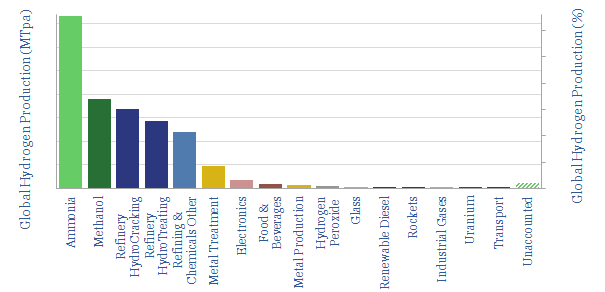

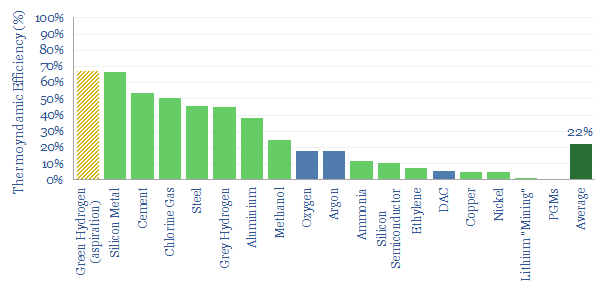

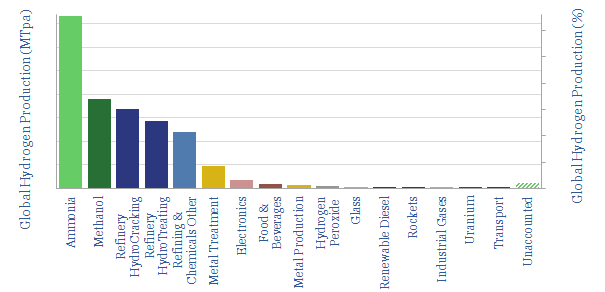

…successful adoption across some of the hydrogen-using industries shown above. Covered technologies used to generate today’s hydrogen include steam methane reforming, coal gasification (with an eye watering 25 tons of…

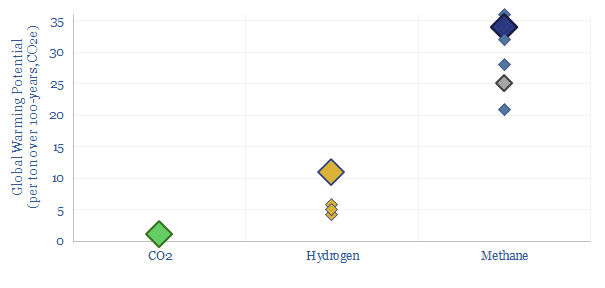

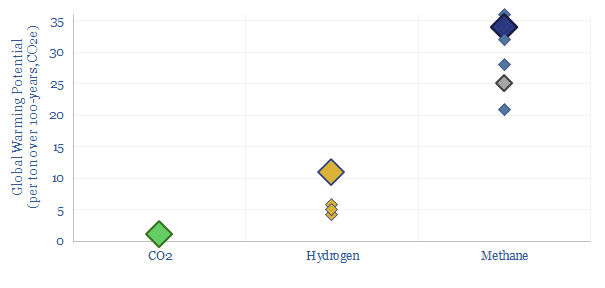

…– 10% hydrogen across a hydrogen value chain. (5) 3x higher hydrogen leakage rates are not an unjustified concern, because the radius of an H2 molecule is about 3x smaller than…

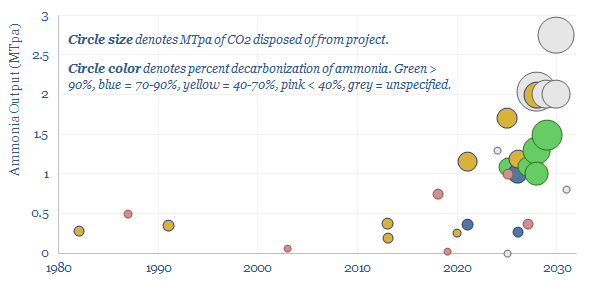

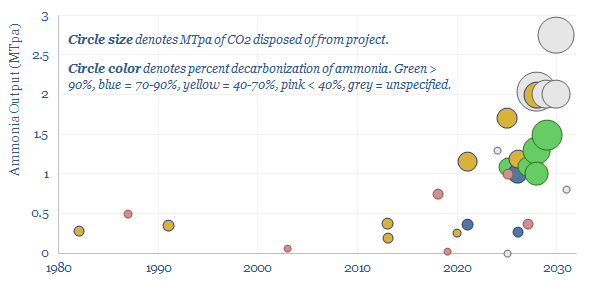

…released when reforming natural gas into hydrogen, which in turn is an input for the Haber-Bosch reaction, which produces ammonia. We have recently written a 12-page deep-dive report, outlining where…