SF6 is an unparalleled dielectric gas, used to quench electric arcs in medium- and high-voltage switchgear. There is only one problem. It is the most potent GHG in the world. Therefore, it may be helpful to find replacements for SF6 switchgear, amidst the ascent of renewables and electrification. This note discusses resultant opportunities in capital goods, plus some minor cost inflation consequences.

Electrical Arcs and Amazing Switchgear?

Our recent research is taking us down the rabbit hole of power-electronics, looking for capital goods opportunities associated with increasingly renewables-heavy grids. For example, wind and solar are more volatile than conventional generation. They do not inherently provide any inertia or reactive power. For an explanation of these effects, and an example of a possible solution, please see below.

Another crucial theme is switchgear, which you can think of as the industrial-scale equivalent of the circuit-breakers and light switches in your house. At the 120-240V voltages in a typical home, flipping these switches ‘off’ is fairly trivial.

But once voltages surpass about 10kV, and especially above 150kV, we are starting to deal with serious amounts of energy. The potential difference on either side of these electrical contacts can be large enough to literally rip the electrons off of air molecules, and form an ‘electric arc’, which is like an electrical lightning bolt, whose core can reach 20,000◦C. For some slightly mesmerizing videos of electric arcs in primary power distribution, see below.

Further downstream, you obviously do not want uncontrolled electrical lightning storms raging through the sensitive and expensive electronic equipment in an industrial facility, every time you turn it on/off, or every time there is a fault on increasingly volatile power grids. Especially if people are in the vicinity. High potential differences will chemically degrade most substances. High enough temperatures will also melt practically anything.

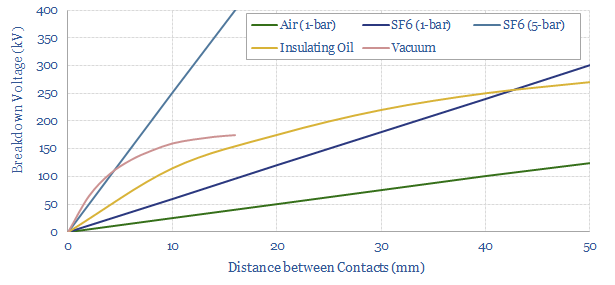

Enter gas-insulated switchgear (GIS). In 1957, Westinghouse began commercializing switchgear containing a compound called SF6, which rapidly gained popularity in the 1970s. At comparable pressures, this gas has 2.5x higher dielectric strength than air (and more at even higher pressures, see below), which means it takes 2.5x more voltage to rip the electrons away and permit current to flow. Moreover, SF6 is ‘self healing’: in a few micro-seconds, any dissociated SF6 molecules will re-combine, so the SF6 can quench multiple electric arcs in quick succession. It has 3.7x higher specific heat than air, absorbing excess heat without transmitting it onwards. It is non-toxic. It is non-flammable. Hence it has become a dominant solution to ‘fill’ the cavities of switchgear and quench electric arcs. There is no other substance known to man with such an incredible array of properties.

Climate Impacts of SF6?

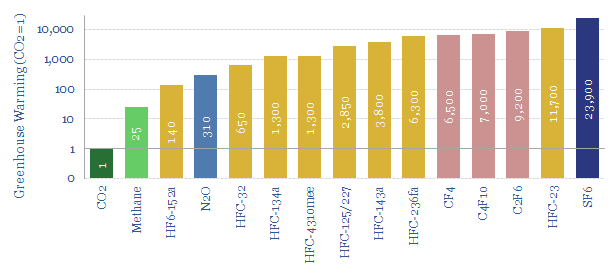

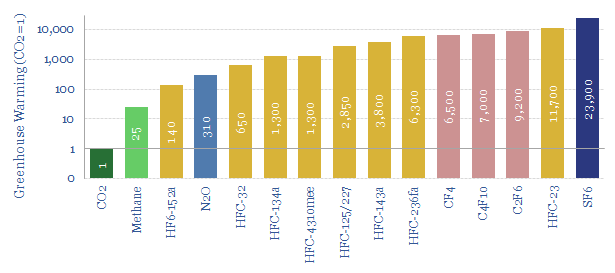

There is only one problem with SF6. It is the most potent greenhouse gas in the world, with around 23,900x higher warming potential than CO2 (chart below). Because of its exceptional stability, it also has an atmospheric lifetime of about 3,200 years, which effectively means that any SF6 released into the atmosphere stays there ‘forever’.

It is important not to sensationalize the climate impacts of SF6. The world consumes around 8kTpa of SF6, of which 80% is used in electrical switchgear, as described above. Especially in Europe, there are stringent regulations to ensure checks and prevent leaks of SF6.

But even if 8kTpa of SF6 were released to the atmosphere — e.g., at end-of-life, when switchgear is retired — then this would be equivalent to about 200MTpa of CO2, or around 0.4% of today’s global emissions. A study in the 1990s concluded that SF6 emissions had so far contributed <0.1% of all historical manmade warming. On the other hand, the $120bn pa market for switchgear will likely grow rapidly from here, with the themes of renewables, EVs and the policy-objective to ‘electrify everything’ (below).

A read-across for gas? There are people out there who look at natural gas’s global warming potential — 80-100x CO2 on an instantaneous basis, 21-25x CO2 over 80-100 years — and argue natural gas should therefore be ‘banned’. This is not our view. We simply think gas users and consumers must mitigate methane emissions (note below). But you cannot help wonder what these ‘abolitionists’ would say about SF6. Should it not be banned as well by the same logic?

Reading through documents from the European Commission, one gets the sense that there is a desire to tighten regulations and lower SF6 usage in the electrical industry. (It has already been banned in other non-essential contexts, such as in double-glazing).

The challenge is that alternative solutions are not practical. One EU document from 2020 notes “it is a challenge to find cost effective, reliable, and safe SF6-free replacements for load break switches… because, compared to vacuum circuit breakers, load break switches are normally simpler, cheaper and maintenance free”. However, the document goes on to argue that “Where the SF6-free alternatives are more costly than switchgear containing SF6, policy intervention is likely to be needed to trigger a transition. As part of the European Green Deal, the Commission has recently launched a review of the EU rules on fluorinated gases”.

Replacements for SF6 — Capital Goods Opportunity?

What are the challenges? Larger footprints are needed for SF6-free switchgear. In other media, it simply takes more space to safely quench an electrical arc. This makes it difficult to replace switchgear at industrial sites with space constraints.

Larger switchgears also tend to use more materials, and require larger manufacturing efforts, which in turn makes their costs 20-30% higher than SF6-using switchgears (and 2x more expensive in some cases).

Finally, SF6 is so chemically inert that it does not react with metallic components or contacts, degrading switchgear over time, whereas other gases will likely require more maintenance over their operating lives.

Nevertheless, there are alternatives, using air insulation, mineral oils, fluoroketones, CO2, epoxy coverings and vacuum-mechanisms to quench electrical arcs. To re-iterate, they are simply more expensive and usually less practical than SF6.

There is a large prize for the capital goods industry, therefore, developing SF6-free alternatives. And we will note some examples below.

- Eaton was the first manufacturer of SF-6 free switchgear, and has shipped 350,000 SF6-free switchgears by 2019, and 15M vacuum-interrupters, under its Xiria product range.

- AirPlus is a mixture of Novec 5110 (C5-PFK) and dry air, commercialized by ABB and 3M. These have been field-tested since November-2015 and have largely behaved as expected. The product range includes a medium-voltage gas-insulated indoor RMU which can operate at 24kV and with a 630A rating.

- g3 is a blend of Novec 471010 (a C4 PFN) and nitrogen, developed by GE and 3M and has been fully type-tested. It has similar performance to SF6 and has been proved up to 420kV. It is being tested at insulated substations by TSOs, including National Grid, with a single substation in SW Scotland saving 1.7 tons of SF6.

- Nuventura has a product using ‘synthetic air’ as an insulator. The product is claimed to match the footprint of comparable SF6 solutions, while having 7-10% lower capex and opex. The product is currently rated up to 1,250A and 12-36kV. We currently see three patents for Nuventura in the EPO database. The company is privately owned, based in Germany and was founded in 2017.

- Other manufacturers of SF6-free switchgear include Meiden, Hitachi, Schneider, Toshiba, Lucy et al. Screening different companies may form the basis of a future TSE research note. Please contact us if this would be interesting or helpful.

What impacts on renewables and electrification costs?

The best way to evaluate the future costs of a technology are to build up a detailed line-by-line cost model, then interrogate each line. Our main conclusion from this exercise, across 500 data-files so far, is that we many cost lines in the build out of renewables and electrification may actually re-inflate in the future. Especially where costs are linked to underlying materials.

Electrical balance of plant usually comprises $100-300/kW of the costs in our wind and solar models, out of $1,000-3,000/kW total costs (breakdowns below). A single circuit breaker might cost $5/kW (maximum capacity basis). A single transformer might cost $12/kW (note below). Generally, one might expect c10-30% reinflation in the cost of switchgear as SF6 is de-prioritized for new equipment in the future. Although we think this is unlikely to add more than 1-2% to the cost of an overall renewables project.

Examples of our research into future renewables costs are linked below. Again, we do not want to sensationalize the issue of SF6. But broadly, we think it may be dangerously incorrect to assume ‘perennial deflation’ for many renewables technologies, as there are many line items re-inflating in our models. We will continue to look for opportunities in power-electronics and materials.