Silicon carbide: production costs?

This data-file captures silicon carbide production costs: spanning from materials grade SiC ($1,500/ton marginal cost, 5 tons/ton CO2 intensity) through to SiC wafers that are used in the electronics industry…

This data-file captures silicon carbide production costs: spanning from materials grade SiC ($1,500/ton marginal cost, 5 tons/ton CO2 intensity) through to SiC wafers that are used in the electronics industry…

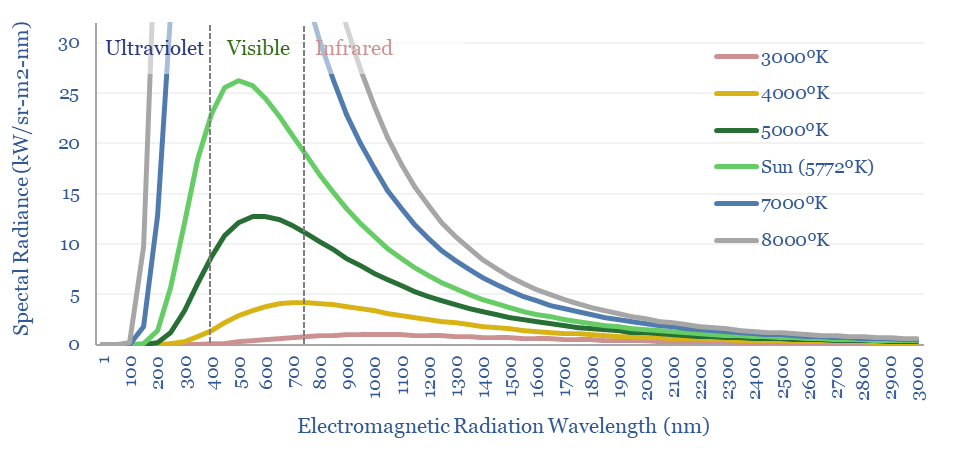

…the conductivity of semiconductors, in spreadsheet format, from first principles, as a useful reference file for our broader modelling of semiconductors, from solar panels to electric vehicles. The basic formula…

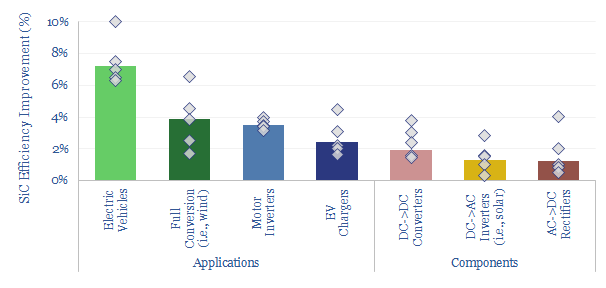

…sector in conventional energy (pages 2-4). The incumbent semiconductor used in 99.9% of electronics and 95% of power electronics is silicon. However, a new entrant is gaining ground. Silicon carbide…

…formulas for semiconductor conductivity (calculations here). Semiconductors are really not very good conductors. This is why a solar panel contains more copper than silicon and always will (page 8). Doping…

…charted the company’s revenues, employee count, market share in MOSFETs, market share in SiC devices, market share in SiC materials, total estimated revenues from SiC and proportionate exposure to SiC….

…digital switches made of semiconductor materials, which allow one circuit to control another. Our overview of semiconductors explains how a transistor works, from first principles, by depicting a bipolar junction…

…substrate; coating the nano-wires with a first silicon layer; then coating the nano-wires with a second, differently shaped silicon layer). Manufacturing costs of Amprius’ silicon anode batteries can be guessed,…

…silicon metal, purified into polysilicon, upgraded into mono-crystalline poly-silicon and ultimately used in solar cells. We estimate silicon explains $0.1/W of the cost of a $0.3/W panel. There is no…

…(e.g., silicon). The same analysis now shows how the maximum efficiency can reach 44%. Cells with multiple semiconductors are already being commercialized. For example, we wrote last year about heterojunction…

…to make 70% of LEDs globally, but also for wide-bandgap semiconductors, such as SiC and GaN, the market leader is a publicly listed German specialist, with 70% market share. In…