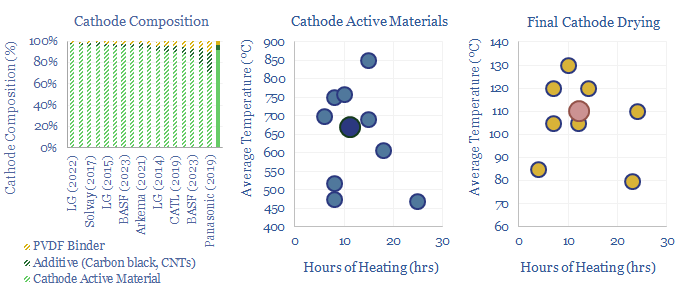

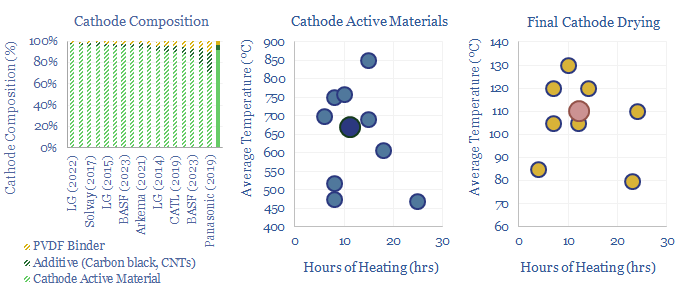

…process, which also explains some of the challenges ahead for battery recycling. https://thundersaidenergy.com/2023/09/28/new-energies-the-age-of-materials/ Cathode manufacturing: ten-stage process? (1) Lithium is sourced as lithium hydroxide or lithium carbonate in the first…

…enormous challenges. What helps is a landscape of different companies exploring different solutions. For a review of how this has helped to de-risk, for example, plastic pyrolysis, see our recent…

Danimer Scientific is a producer of polyhydroxyalkanoates (PHA), a biodegradable plastic feedstock, sold under the brand-name Nodax, derived from the bacterial metabolism of vegetable oils (e.g. canola oil). There are…

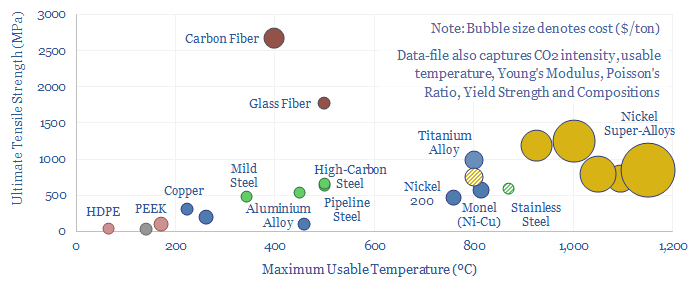

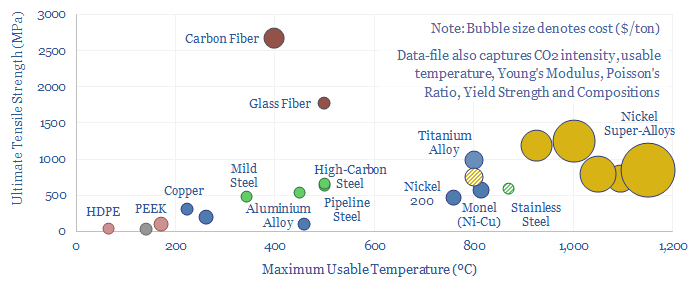

…stress, additional stress will not cause further elastic deformation, but instead, will cause plastic deformation. When this stress is removed, then the material does not return to its original shape….

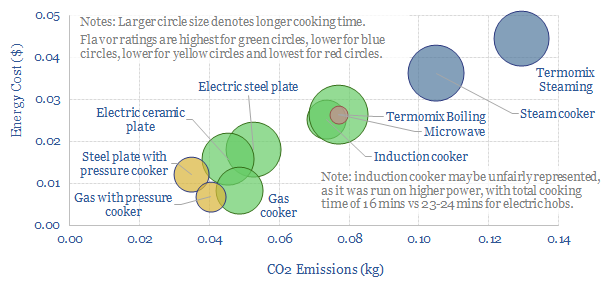

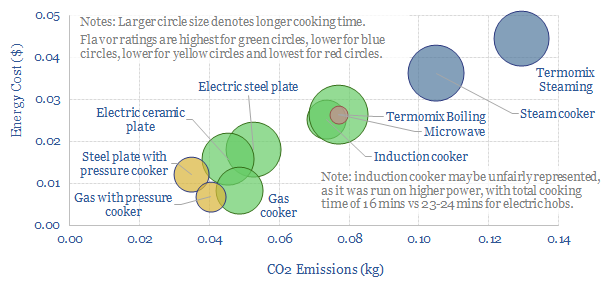

…grant the complexity around measuring efficiency in a process as simple as cooking potatoes, I can promise you, it is more complex in the industrial production of steel, cement, plastic,…

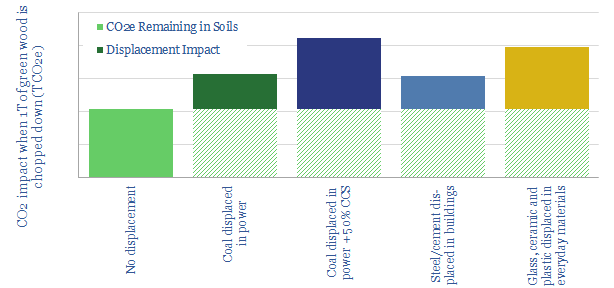

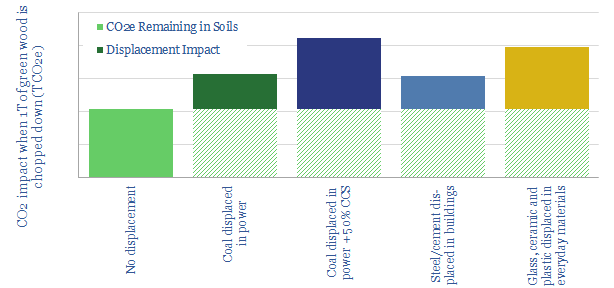

…of CO2 per ton of cement, around, 1.3-1.5T of CO2 per T of glass and ceramic, and as much as 5T of CO2 per ton of plastic (chart below). The…

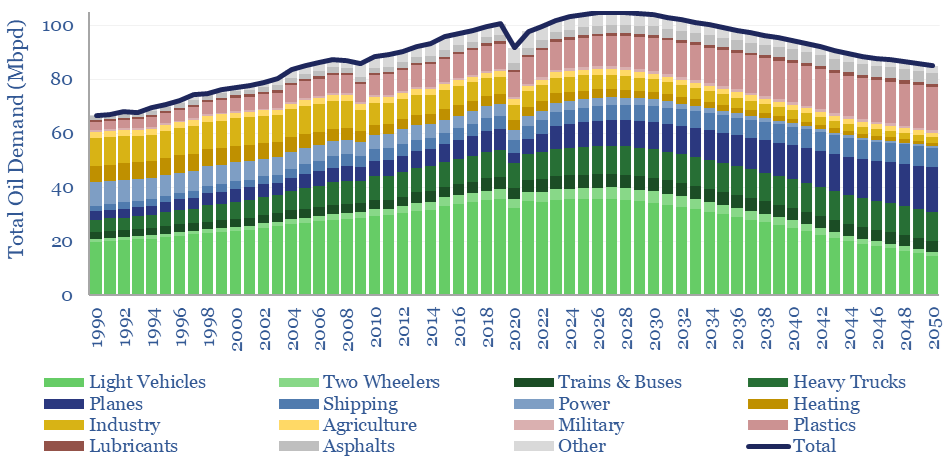

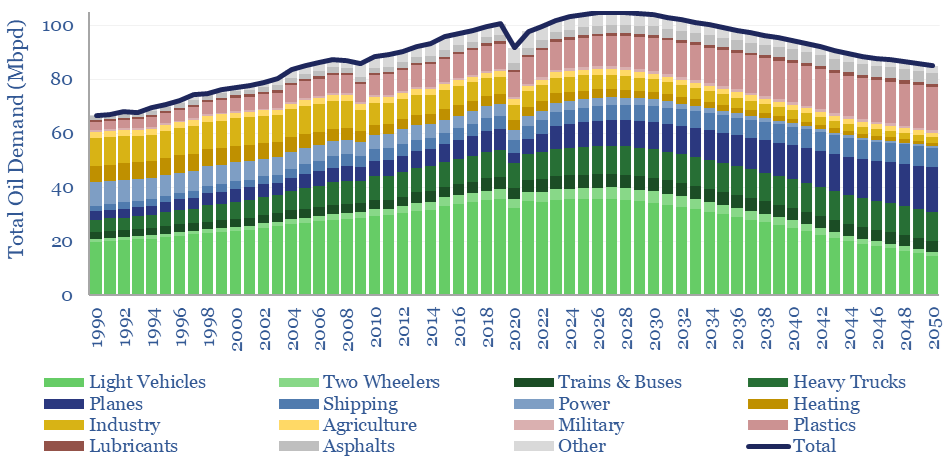

…in June-2024, to reflect 2023 data, and our latest outlook into changing vehicle fleets and long-term plastic demand. Underlying workings are shown in seven subsequent tabs, covering light vehicles, trucks,…

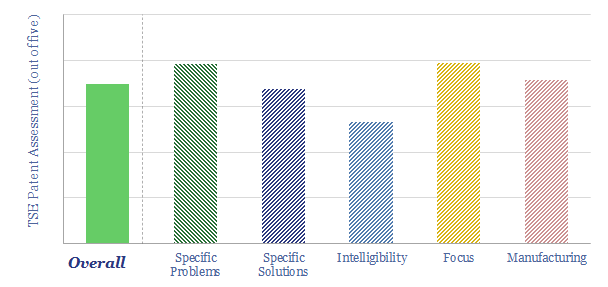

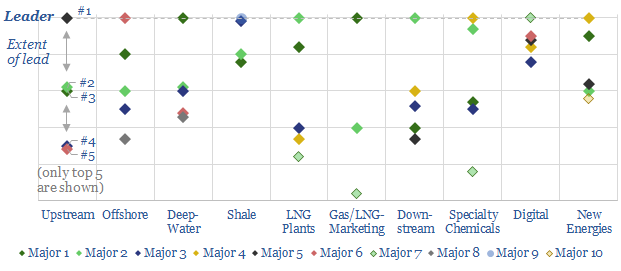

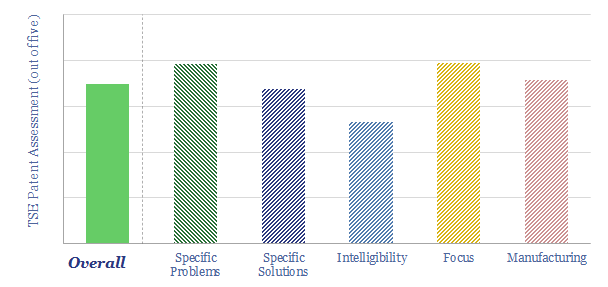

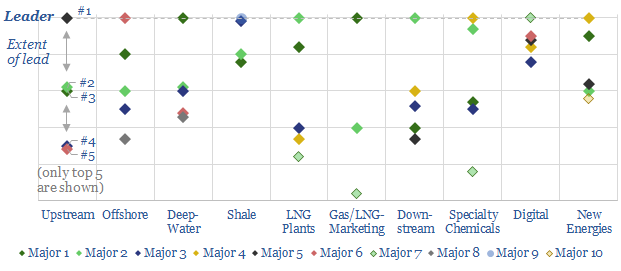

Technology leadership is crucial in energy. It drives costs, returns and future resiliency. Hence, we have reviewed 3,000 recent patent filings, across the 25 largest energy companies, in order to…

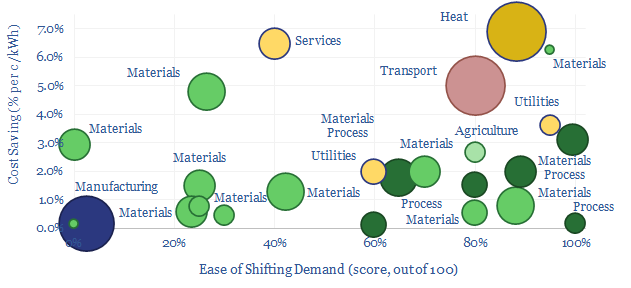

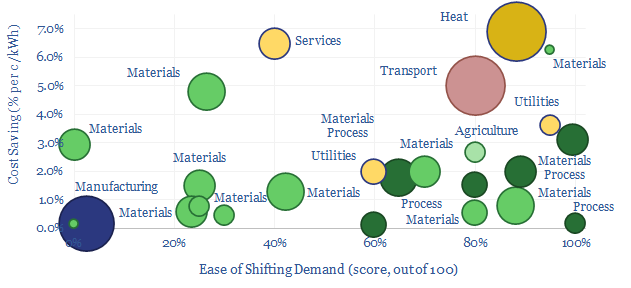

…potential and economic potential. An electric arc furnace for steel recycling might typically have a low utilization as it is constrained by the ability to source scrap. A cement plant…

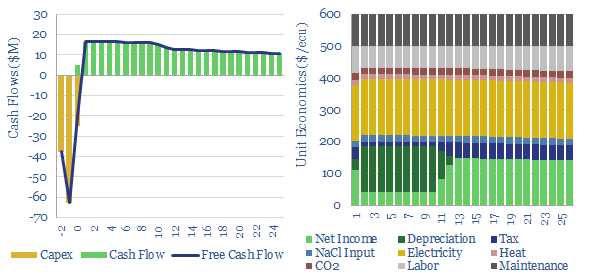

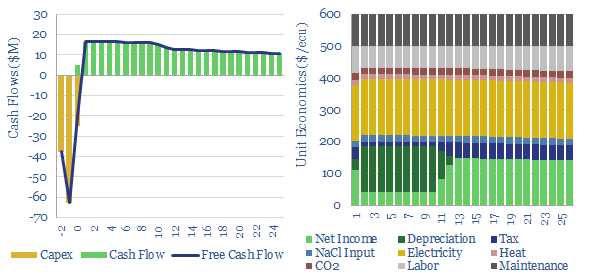

…models for energy transition and broader industrial models, such as paper products, renewable diesel, carbon fiber, refining, battery recycling, some CCS and Direct Air Capture. HCl is also an input…